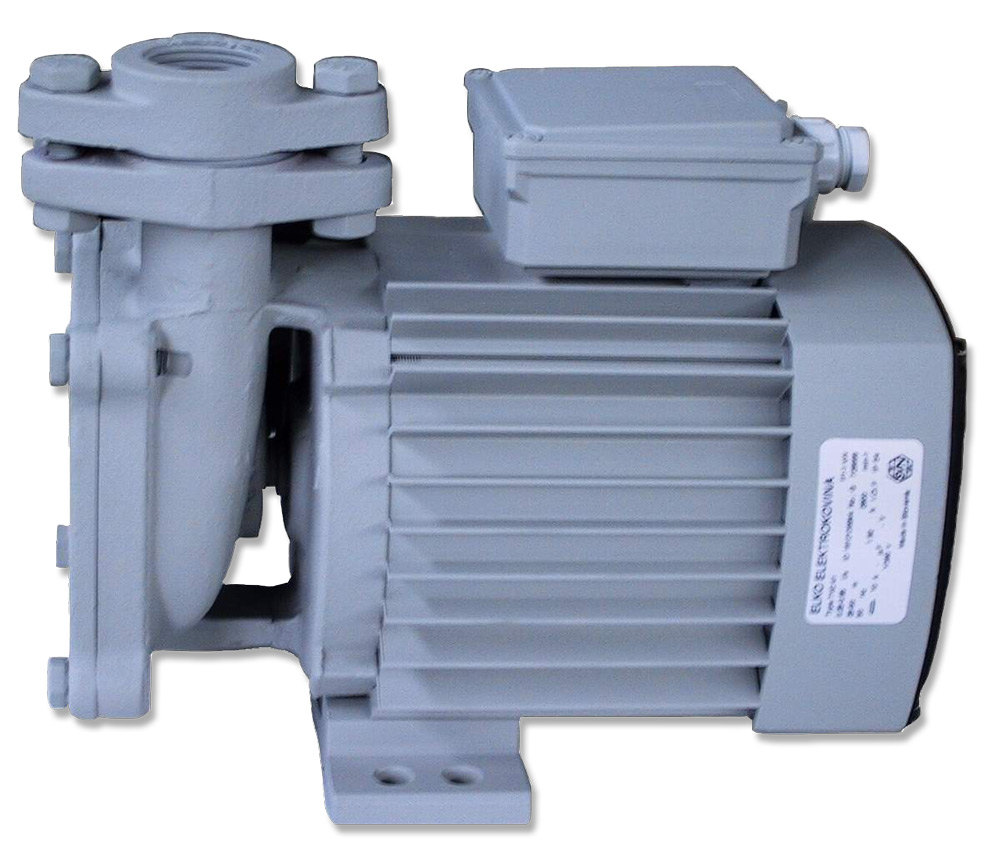

STANDARD DIN PUMPS

Standard DIN pumps

Description

Standard DIN pumps are designed to pump water that does not contain solid particles. They can be used to pump cold or hot water up to 140°C. They have a versatile use in industry and agriculture, especially for irrigation. They can be used as circulating pumps for central heating or cooling installations and are also intended for swimming pool equipment. In technological processes, they are useful for pumping all chemically neutral liquids that do not contain abrasive particles with a viscosity similar to the viscosity of water.

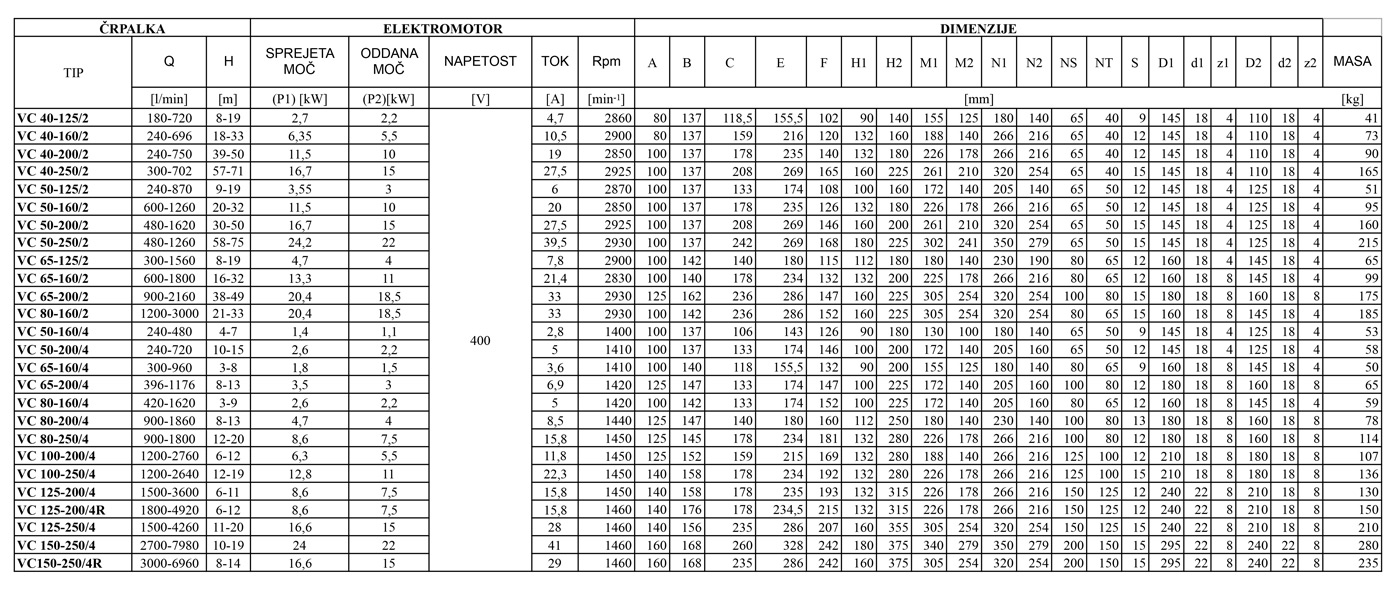

Technical characteristics

Flow: from 180 to 8000 l/min

Lifting pumping height: up to 76m

Motor power: 1.1 ÷ 22kW

Power supply: 3-phase (400V)

Medium temperature: from 0°C to + 140°C

Ambient temperature: from 0°C to + 40°C

Suction height: up to 7m

Maximum permissible operating pressure of the housing: 10bar

Weight: 41 – 280kg

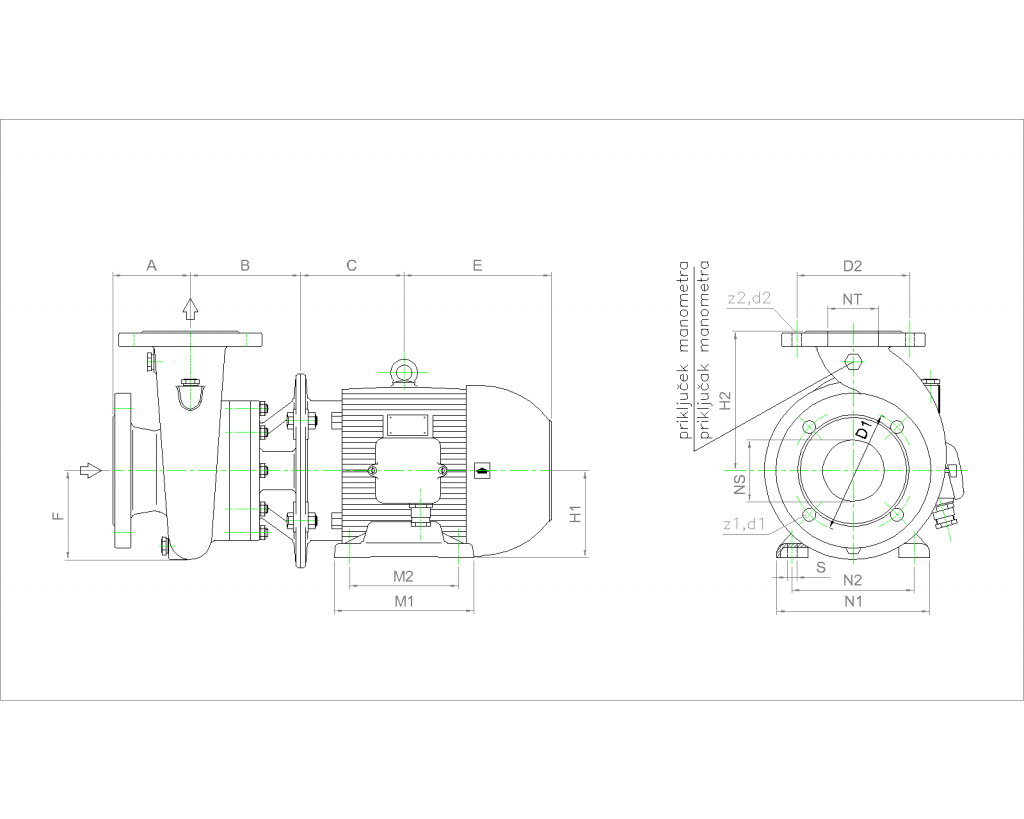

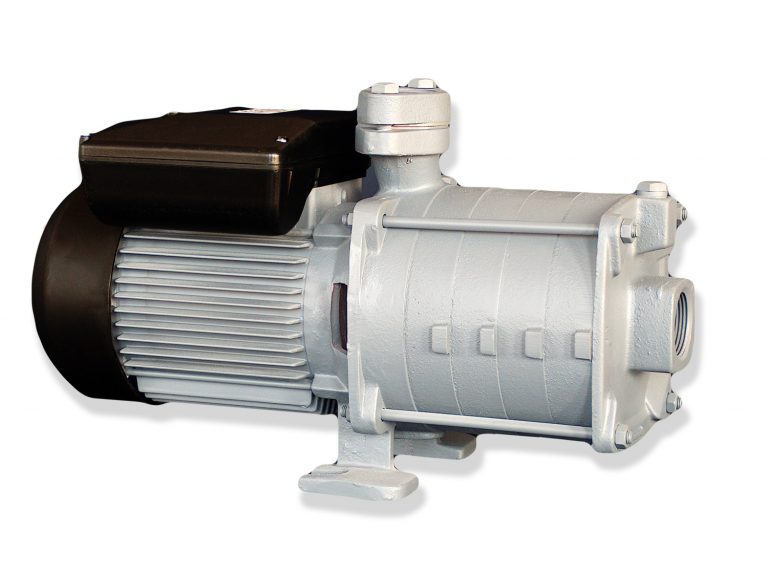

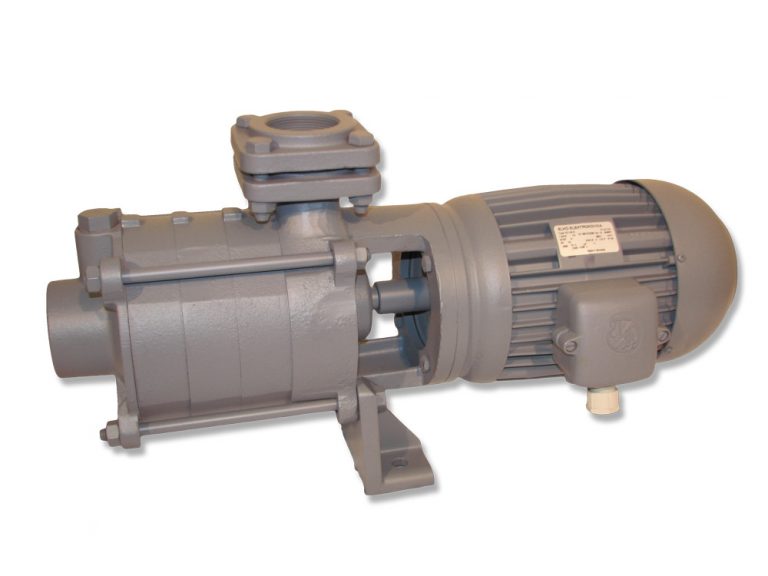

All pumps are single stage with a spiral housing. They are made in a monoblock version. A feature of standard DIN pumps is the joint shaft of the electric motor and the pump part. The shafts are made of stainless steel, and the pump parts are made of quality gray cast iron. The sealing of the pumps at the shafts is carried out with seals with sliding rings which allow a permanent pressure of 10 bar in the pump housing. The electric motors all come with three-phase design. They are equipped with legs that serve to attach the unit to the base. The mechanical protection of the electric motor is IP 54 according to IEC 34-5. This is protection against accidental contact, settling of dust particles in the engine and against splashing water from all directions. The design of the pumps meets the requirements of DIN 24255 which prescribes the connection dimensions and characteristics of the pumps. This means that it is possible to replace any equivalent pump built to a given standard with a standardized pump, without the need to rearrange the installation during replacement. The type designation of the pump indicates the size of the pressure connection and the diameter of the impeller. The spiral housing has three G¼ connections which are intended for the connection of the manometer, for venting or filling the pump with water and for emptying the pump. All G¼ connections are closed with threaded plugs.

Purpose of use

– for drinking water management

– domestic use for the care of single-family houses

– supply of facilities with hot and cold water

– for irrigation systems

– car wash

– farms

– pool technique

– industrial purposes

– for pumping chemically neutral liquids

– plumbing systems

– watering and irrigation systems

– central heating circulators

– cooling systems